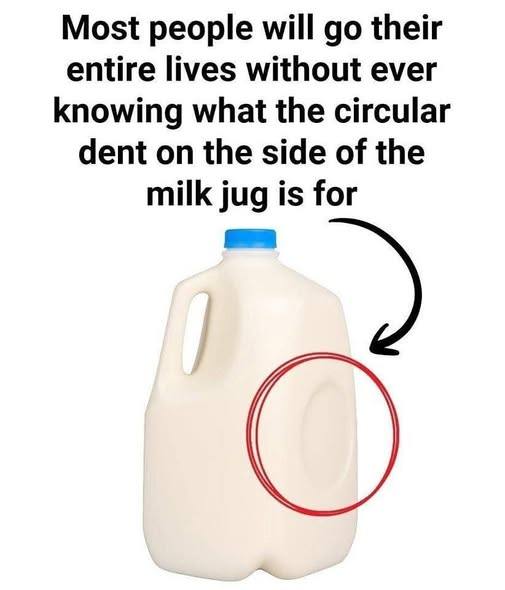

4. It Helps During the Manufacturing Process

Milk jugs are made using a process called blow molding. In this process, hot plastic is inflated inside a mold to create the final shape.

The circular dent helps control how the plastic expands and cools during manufacturing. It ensures even thickness and reduces weak points in the container.

5. It Can Signal Freshness Issues

Here is something interesting: if a milk jug appears bloated or the dent is pushed outward significantly, it may indicate spoilage. As milk spoils, bacteria can produce gases. This can create internal pressure, causing the jug to swell.

If you notice unusual swelling, it is best to check the smell and expiration date before consuming.

A Simple Design with Smart Purpose

The circular dent is not decorative. It is a carefully designed feature that:

– Protects against pressure changes

– Strengthens the container

– Prevents cracking

– Supports safe transport

– Improves manufacturing efficiency

Everyday objects often hide clever engineering solutions. The next time you pour a glass of milk, you will know that even that small circular dent has an important job.

Small details often make the biggest difference.