Why Milk Jugs Have That Circular Dent – The Surprising Engineering Secret Explained

Trending Keywords: why milk jugs have dents, milk jug design explained, plastic bottle engineering, blow molding process, food packaging science, everyday design secrets, gallon milk container facts

Why Milk Jugs Have That Circular Dent: The Clever Design Behind It

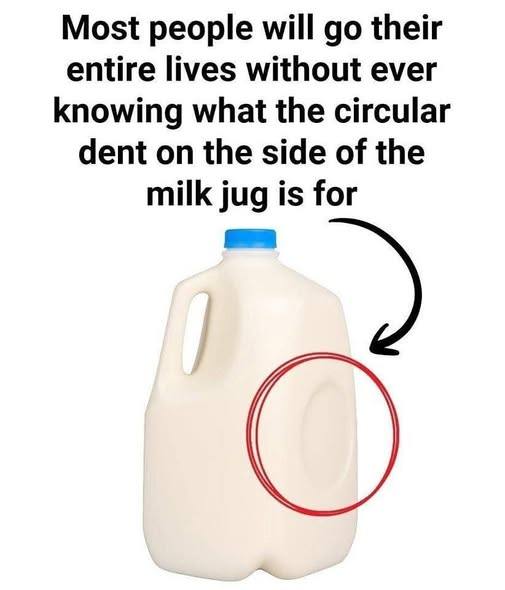

Have you ever noticed the circular dent on the side of a plastic milk jug? Many people assume it is simply a design detail or even a manufacturing defect. However, that small indentation is actually a smart piece of engineering. It plays an important role in keeping your milk fresh, your jug strong, and your kitchen safe.

Let us explore the real reasons behind this everyday design feature.

1. It Protects the Jug from Cracking

Milk jugs are usually made from high-density polyethylene, a flexible but durable plastic. During transport and storage, milk experiences temperature changes. When milk is cooled after pasteurization, the liquid contracts slightly. This can create internal pressure changes inside the container.

The circular dent acts as a flexible buffer zone. If pressure inside the jug drops or increases, the dent can move inward or outward slightly. This helps prevent the jug from cracking or collapsing. In simple words, it works like a built-in shock absorber.

2. It Compensates for Temperature Changes

Milk is stored cold, but it is often filled at a different temperature. As the milk cools in the refrigerator, it shrinks slightly. Without flexibility in the container, this could create vacuum pressure that might deform the bottle.

The dent allows the plastic to adjust naturally. Instead of the entire jug warping or becoming misshapen, the dent absorbs the movement.

3. It Improves Structural Strength

At first glance, it may seem strange that a dent would make something stronger. However, in engineering, curved shapes distribute stress more evenly than flat surfaces.

The circular indentation increases the structural integrity of the jug. It helps the container resist outside pressure, such as when jugs are stacked during shipping or stored tightly together in refrigerators.

4. It Helps During the Manufacturing Process